Pockels Cell Laser Modulators

All lasers are susceptible to noise introduced by their power supplies. Switching power supplies, which have become common because of their efficiency and small size, are particularly likely to introduce laser system ripple at frequencies ranging into the tens of kilohertz. Such interference, when it affects the light beam in confocal microscopy systems, can be especially troublesome to diagnose and remove. The beam intensity of continuous wave lasers can be stabilized by either electronic control of the tube current or through utilization of external components that modulate the light intensity. This interactive tutorial examines how the Pockels cell modulator operates to stabilize laser beam intensity.

Error processing SSI file--> -->

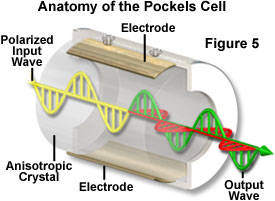

The tutorial initializes with a simplified cutaway diagram of a Pockels cell, which contains a cylindrical anisotropic crystal sandwiched between two electrodes, appearing in the window. Incident polarized laser light (650 nanometers by default) enters one end of the cell and undergoes an oscillating 90-degree rotation of the polarization vector due to refractive index changes in the anisotropic crystal induced by the electrodes. The Switching Speed slider can be used to control the frequency of the electrode switching (or to disable switching), and the Wavelength slider adjusts the incident wavelength between a range of 300 to 800 nanometers.

External components utilized to provide stabilization of laser intensity generally employ a fast feedback system to control an electro-optic modulator that minimizes fluctuations in beam power. The external Pockels cell modulator (see Figure 1) is available from a number of manufacturers, and can be used, in principle, to stabilize the output power of any continuous wave laser. Large intensity fluctuations (up to approximately 50 percent) can be corrected by this technique, but with a proportional reduction in total output power. A wide range of correction capability is important with many systems. The helium-cadmium laser, for example, can exhibit variation in output power of around 20 percent, due in part to strong plasma oscillation between certain beam frequencies. Systems exist that are reported to be suitable for regulating cw and mode-locked lasers to within a few hundredths of a percent of their output power, and over a frequency range from direct current to several hundred megahertz, with noise attenuation of 500:1, or greater.

The basic components of a Pockels cell modulator are presented in Figure 1. External devices for regulating laser output intensity, similar to the Pockels cell design, are sometimes categorized or marketed under the term noise eaters. The fundamental concept behind electro-optic modulators utilizing the Pockels effect is based on a mechanism for varying the polarization properties of the cell at an extremely rapid rate to provide a variable beam attenuator for control of laser intensity. The polarization state of the laser output determines the total attenuation of the modulator, but up to 80 percent transmission is possible. Following emission from the laser head, a portion of the beam is diverted by a beamsplitter to a photodiode, which compares the intensity to a preset (selectable) reference intensity, and amplifies the difference signal so that it can drive the electro-optic Pockels cell modulator. The amplified signal produces a refractive index change in the cell that rotates the plane of polarization, thereby varying the beam attenuation in proportion to the difference voltage that is applied. Among substances that exhibit a change in polarization properties with changes in electric field (Pockels effect) are potassium dihydrogen phosphate and lithium niobate, and crystals of these materials are commonly utilized in the beam modulators.

In situations where randomly polarized light is stabilized by a Pockels cell system, the modulator must be positioned between crossed polarizers, and further consideration is necessary to minimize the effects of these additional components on the beam stability. Because dust, vibrations, and other interferences can alter beam stability at any point in the optical path, it is important that external stabilizers are placed as close as possible to the specimen position in optical microscopy systems. This effort will ensure that the most stable beam is delivered to the specimen.